SD-JB-1600-6 four-axis plate rolling machine parameters

Four-roller CNC rolling machine

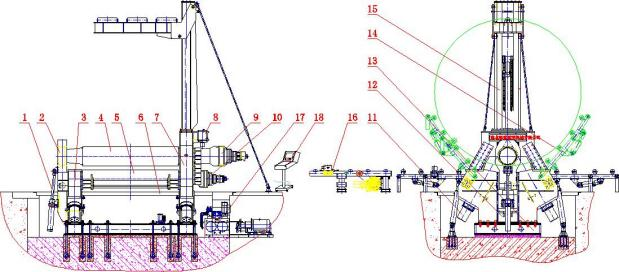

Illustrations of similar equipment (pictures are for reference only, the actual design shall prevail)

Illustrations of similar equipment (pictures are for reference only, the actual design shall prevail

1 Overturn cylinder 2 Overturn frame 3 Left frame 4 Upper roller 5 Side roller 6 Lower roller 7 Right frame 8 Balance device 9 Upper roller drive device 10 Lower roller drive device (optional) 11 Side roller cylinder 12 Lower roller cylinder 13 Base 14 Side bracket (optional) 15 Upper bracket 16 Electric feeding platform (optional) 17 Hydraulic system 18 Electronic control system

1. Overview of the subject

The hydraulic CNC five-axis plate rolling machine is one of our company's flagship products. It is specially designed and manufactured for rolling cylindrical workpieces made of stainless steel, galvanized sheets, cold plates and other metal materials. And has a number of national related patents. Long-term production and processing has enabled our company to accumulate rich technical experience, making our equipment at a relatively advanced level. The machine tools produced by our company have stable performance and easy operation. The CNC five-axis plate rolling machine produced by our company has the advantages of good rolling roundness, no need for separate pre-bending, small rolling straight edges, and one-click start of rolling forming.

1-1. Main body overview

This machine is fully hydraulically driven, digitally controlled, with advanced structure, superior performance and high efficiency. Features of our CNC plate bending machine: 1. The side rollers move linearly to increase work stability. 2. Both sides of the pressure roller are controlled by absolute encoders for synchronization.

The following users are suitable for using this CNC plate rolling machine:

1. First time users of plate rolling machine, because this is an easy-to-operate plate rolling machine

2. Operators lack inspection and require higher productivity

3. Require higher precision and improve quality

4. Hope to reduce operators and reduce labor costs

Features of this machine:

1. Full hydraulic drive, high efficiency and energy saving (the driving power is equivalent to 60% of the traditional one). Compared with the traditional three-roller plate rolling machine, the rolling operation is safer and more reliable;

2. Permanent lubrication technology (no need to refuel during the bearing life);

3. The clamping pressure is adjustable (there is no slipping, and the productivity is 50%-80% higher than that of a three-roller plate rolling machine). The clamping force of the plate between the upper and lower rollers can be adjusted differently through the pressure regulating valve of the hydraulic station. The corresponding required pressure when rolling the thickness and width of the plate;

4. It can roll a cylinder with a minimum diameter of 1.3 times the diameter of the upper roller. When the end of the rolled plate is pre-bent, the length of the straight edge is smaller than that of other types of plate rolling machines.

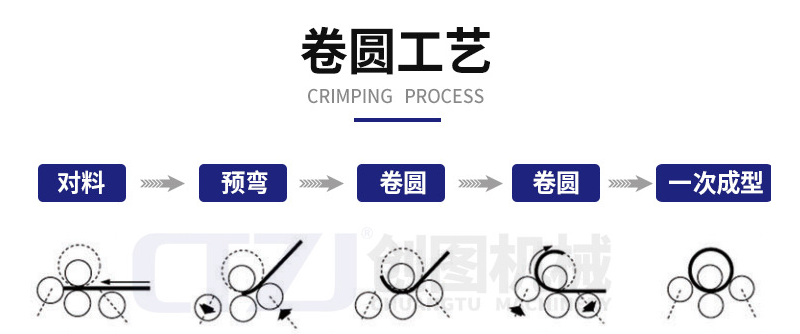

2. Working principle (see picture)

3. Main technical parameters

Model SD-1500-5

Upper roller diameter Φ 170 ㎜

Lower roller diameter Φ 160 ㎜

Side roller diameter Φ 140 ㎜

Maximum rolled plate thickness 6mm

Maximum pre-bent plate thickness 4.8mm

The maximum width of the rolled plate is 1500mm

Work roll drive type Upper roll hydraulic motor drive

Yield limit of plate ≤245Mpa

Rolling speed about 6m/min

Pre-bent remaining straight edge ≤1.5 plate thickness

Minimum drum diameter: about Φ250mm

Total equipment power 5.5KW