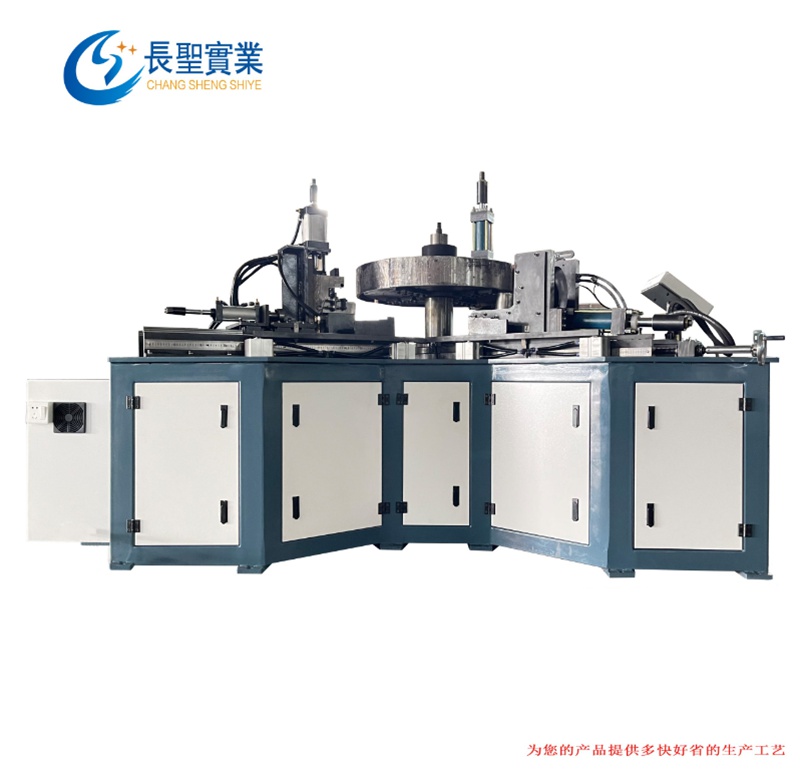

The Vibrating Screen Low Barrel Flap Puller is an essential piece of machinery used in the manufacturing process of flanging machines. These machines are widely used in industries such as automotive and construction to create cylindrical shapes in metal sheets. The low barrel flap puller component is responsible for pulling the metal sheets through the rollers of the machine, ensuring precision and accuracy in the final product. Flanging Machine fabrication companies in China have become increasingly popular due to the country’s expertise in manufacturing complex machinery components. Therefore, the availability of high-quality Vibrating Screen Low Barrel Flap Puller from Flanging Machine China has increased significantly, making these machines more affordable and accessible to global markets.

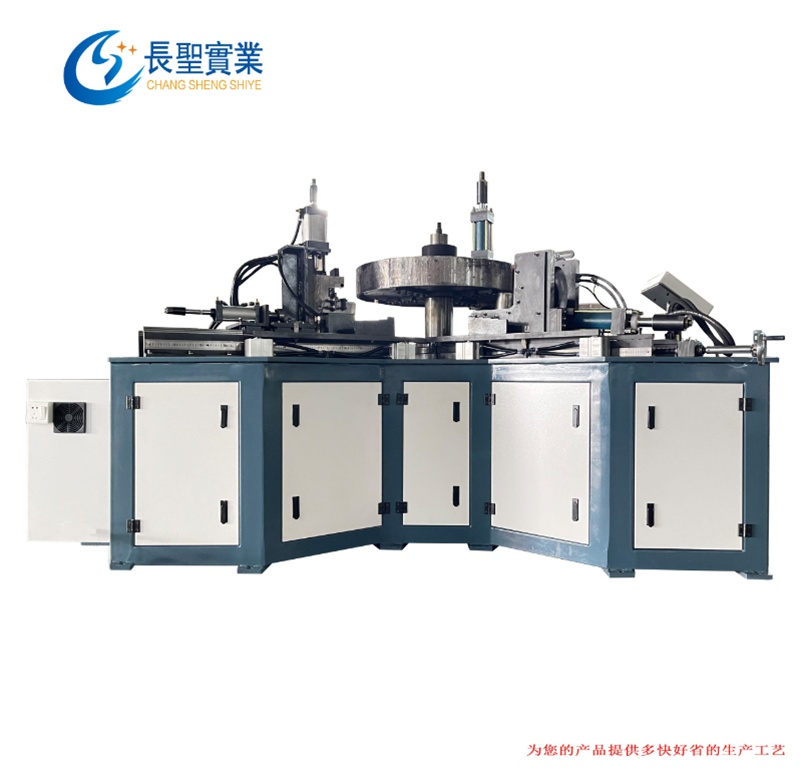

| Total power of equipment | 42kw | Processing diameter (mm) | 500-2000 | |

| power type | 380v three-phase four-wire | Processing length (mm) | 100-1500 | |

| Equipment Specifications | 4000x2500x1700 | Processing thickness (mm) | carbon steel 6mm | |

| equipment weight | 6.4T | device function | Flanging Folding Punching Secondary Pulling | |

| control method | Plc | Punching accuracy | Plus or minus 1MM | |

| drive mode | Electro-hydraulic drive | Punching diameter | 5-16MM | |

| Operation interface | touch screen | Number of punching holes | 0-100 equal division | |

| hydraulic pressure | 14mpa | |||

| Equipment features: simple operation, stable operation, good flanging flatness, punching will not cause errors due to wear of mechanical parts. The equipment is designed for the vibrating screen and can basically complete all the functions of the vibrating screen. | ||||