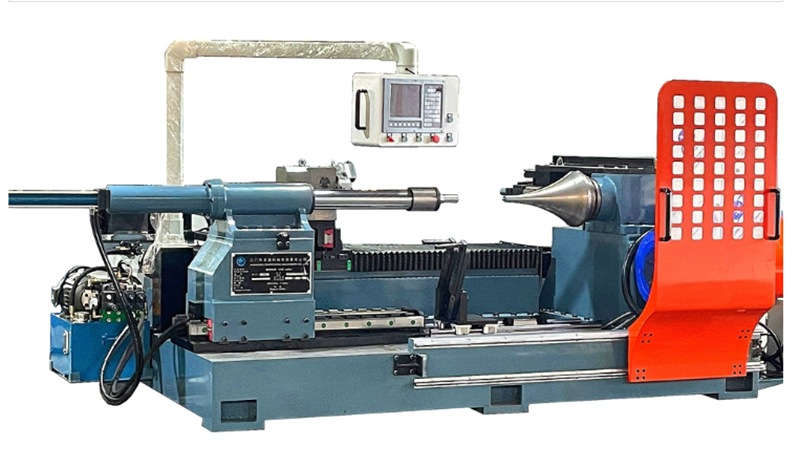

1、CNC Heavy Duty Spinning Machine has mature CAD drawing and programming software functions, the track of runner movement can be straight line, circular arc, multi-circular arc connecting line and combined curve, etc., and input into the computer for road-time standardized programming.

2、Spinning Machine distributor design c operator can input process parameters and spinning time through keyboard and operation panel, and can edit, store and call at will.

3、 Spinning Machine makers set the core mold profile has a “copy” protection function, that is, in the process of adjusting and recording back to demonstrate, the spin wheel will not collide with the core mold.

4、The machine can pause the feed speed and spindle speed in the automatic program. With travel limit protection, software and hardware limit protection in the control system, fault detection and alarm functions.

5、Automatic fault detection, automatic diagnosis and overload protection for each unit at power-on.

6、According to the user’s requirements, it can realize the spin forming of various shaped parts and ensure that the workpiece’s shape surface, diameter, thinning rate and other related dimensions meet the requirements.

7、Complete the functions of trimming, flanging, crimping, indentation and rolling processing on the same machine.

| Name | Parameters | Name | Parameters |

| Power supply type | AC 380v three-phase four-wire | Maximum spin product diameter | 850 |

| Spindle speed | 0-1500 rpm | Spinning thickness (iron plate) | 5 |

| Air pressure | 0.5-0.8Mpa | Spinning thickness (aluminum plate) | 10MM |

| Spindle center height | 400MM | Spinning thickness (stainless steel plate) | 3 |

| Axial travel | 800mm | Maximum spin product height | 800 |

| Radial travel | 400MM | Pressing power | Hydraulic |

| Tail top travel | 800mm | Control System | Deans |

| Positioning accuracy | 0.02mm | Spinning structure form | Horizontal |

| Automatic refueling system | AC220V 25W1 | Warranty Period | 1 year |

| Mountable tool positions | 6 positions | Servo type | Absolute Servo |

| Input method | Handwheel teaching / CAD guide | Equipment weight | 4200KG |

| Equipment appearance size | 3500x2300x1700 | Mold mounting thread | Flange Mounting |

| Use: The machine is suitable for lamps and lanterns, cookware, handicrafts and other industries. It can complete the batch production of barrel type, cone type, parabolic type, horn type, slug type and other series products. | |||